Meeting Cleanroom Standards?

8 March 2023

1. What is a cleanroom?

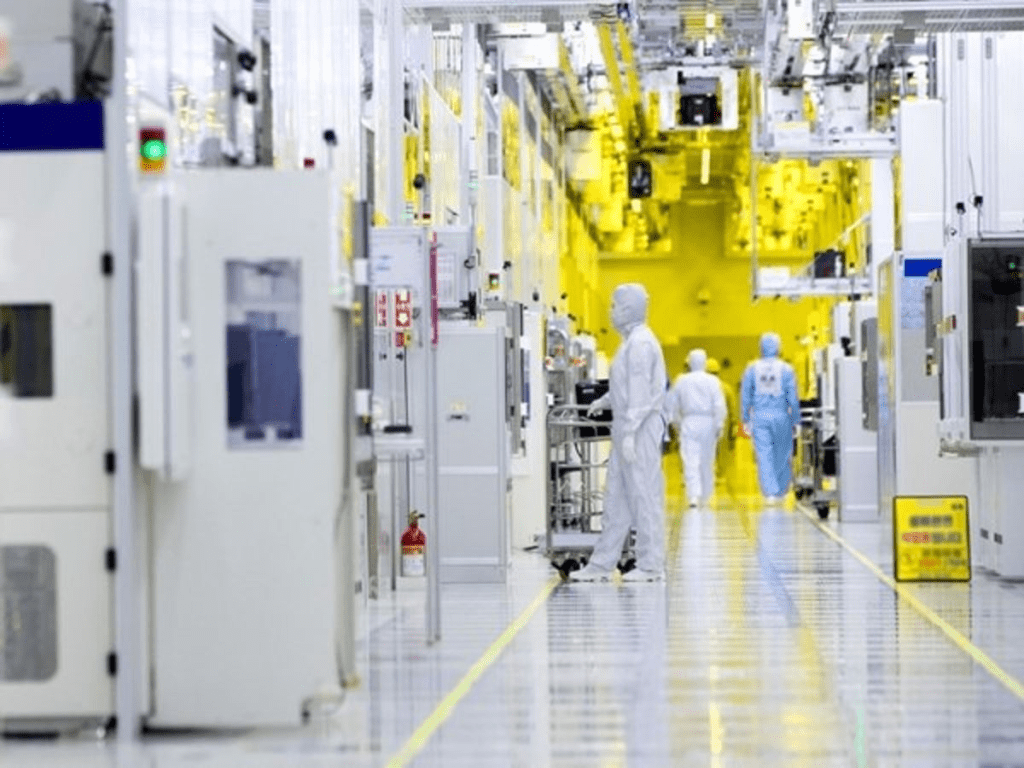

A cleanroom is a controlled environment with low levels of pollutants such as dust, particles and chemical vapours. These cleanrooms are used in nearly every industry in which even the smallest particles can affect the manufacturing process.

Cleanroom standards are practised in industries such as semiconductor manufacturing, pharmaceuticals, food manufacturing and life sciences. Several factors like humans, machinery and equipment need to be taken seriously in order to maintain the clean room standard. To put it simply, contamination ruins the manufacturing process and cleanrooms are here to prevent that.

The machines manufactured must fulfil the clean room standard, just like our chemical mixing system does. For example, our machines are able to cater for cleanroom environment usage. Our chemical mixing systems are assembled in a controlled environment, going through DI water rinsing to prevent contamination, before being sent to the customer.

2. Humans? They contribute to contamination?

Humans are typically “unwelcome” in the cleanroom environment and the number of people allowed in a clean room is notably small. We, humans, carry along lots of pollutants with us, such as fallen hair and sweat plus the dirt and dust particles on our clothing. In every passing minute, humans give off millions of particles through their skin and breath.

Humans also tend to have exaggerated or fast movements when walking, working or talking. These hectic movements will interfere with the procedures and create air turbulence, causing the uncontrollable distribution of particles. The slightest amount of particles in a cleanroom from an object or human can drastically affect the outcome of experiments.

3. How to prevent contamination?

One of the ways employees prevent contamination, is to wear proper cleanroom clothing. These clothing include boots, shoes, aprons, face masks, coveralls, lab coats, gloves, hoods, hairnets and shoe covers.

Proper cleanroom clothing is used to prevent the spread of the substances released from the person’s body and contaminating the environment. The cleanroom clothing itself should not release any particles to prevent contaminating the environment.

The second prevention method is where employees adapt to the velocity of the clean room and plan out their actions in advance, not succumbing to hectic activity in order to keep the number of particles at bay.

Lastly, only authorized people who are specifically trained and equipped are permitted access to the cleanroom. This means that clean rooms are prohibited areas.

Just like us, we have clean room experience. We always follow these requirements when assembling parts in the clean room, using DI water for machine testing instead of normal water. The piping joints are seamlessly fused with IR (infrared) fusion welding. In all, our machines are equipped with these features that can fulfil the customer’s clean room standard requirements.

In summary, cleanrooms help manufacturers keep contamination away and at bay. By following rules and procedures, authorized employees are able to maintain the manufacturing process in a cleanroom. Machines work better when used in controlled environments.